New high water mark for Amray project

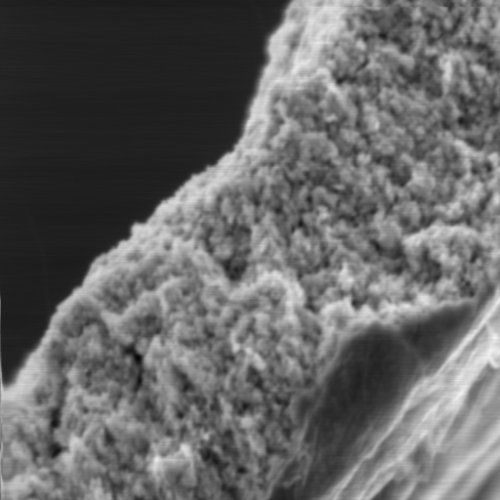

The above image is a cross section of a sputtered copper film on the order of 25 um thick captured at 2,000X magnification. The speed improvements that were made to the SEM_control software have been a huge help. It is now much easier to navigate around the sample and focus the beam. This, in addition to a lot of operator improvements have helped to obtain the highest resolution image taken yet! I have been learning to use the final aperture, the spot size and the beam alignment, helping to push the instrument into the range of being a useful microscope.

The above image is a cross section of a sputtered copper film on the order of 25 um thick captured at 2,000X magnification. The speed improvements that were made to the SEM_control software have been a huge help. It is now much easier to navigate around the sample and focus the beam. This, in addition to a lot of operator improvements have helped to obtain the highest resolution image taken yet! I have been learning to use the final aperture, the spot size and the beam alignment, helping to push the instrument into the range of being a useful microscope.

I would also like to acknowledge the help I’ve received from the users of the Microscopy Listserver. Many thanks to them for their advice on microscope settings, disassembly and cleaning.

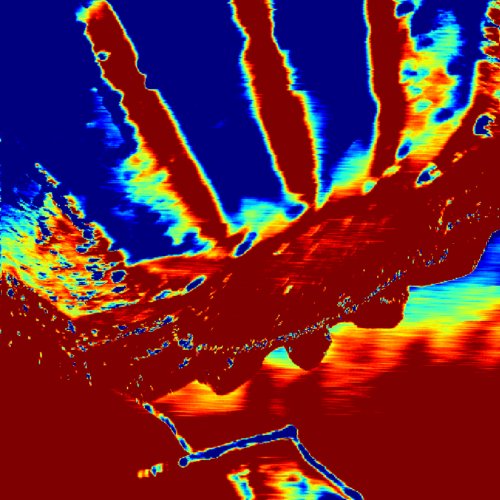

Today for the first time the microscope was turned over to the control of the SEM_control software in place of the original analog scan generators and CRT screens. The result is a pretty good first step, the raster scan is clearly working with the signal recording and I was able to capture this image of a small gear on the sample stage at 50X magnification. I still have a long laundry list of improvements I would like to make to the program to improve the speed and useability of the program.

Today for the first time the microscope was turned over to the control of the SEM_control software in place of the original analog scan generators and CRT screens. The result is a pretty good first step, the raster scan is clearly working with the signal recording and I was able to capture this image of a small gear on the sample stage at 50X magnification. I still have a long laundry list of improvements I would like to make to the program to improve the speed and useability of the program.

The procedure for checking the vacuum system is to isolate the pump using the valves. Then opening each successive portion of the vacuum system and monitoring the pump down time. All of the parts of my microscope seem to pump down well but when the specimen chamber is pumped the ultimate pressure is a little higher than when it is isolated. There are two possible reasons for this behavior. First, the comparatively large surface area of the specimen chamber could simply be out gassing, releasing gas from the chamber surface. Second, the sample chamber has many penetrations any of which could be leaking. I noticed a very small change in the pressure by changing the position of the final aperture. This final aperture has several sliding o-rings to create a seal and is a likely spot for a leak. I ordered new o-rings for this feedthrough.

The procedure for checking the vacuum system is to isolate the pump using the valves. Then opening each successive portion of the vacuum system and monitoring the pump down time. All of the parts of my microscope seem to pump down well but when the specimen chamber is pumped the ultimate pressure is a little higher than when it is isolated. There are two possible reasons for this behavior. First, the comparatively large surface area of the specimen chamber could simply be out gassing, releasing gas from the chamber surface. Second, the sample chamber has many penetrations any of which could be leaking. I noticed a very small change in the pressure by changing the position of the final aperture. This final aperture has several sliding o-rings to create a seal and is a likely spot for a leak. I ordered new o-rings for this feedthrough. To test the many penetrations and sliding o-ring seals in the specimen chamber door I found a blanking plate of the correct size and pumped down the specimen chamber with this in place. I did not observe any changes in the pressure of the chamber with this door in place so I feel confident that these feedthroughs are sealing.

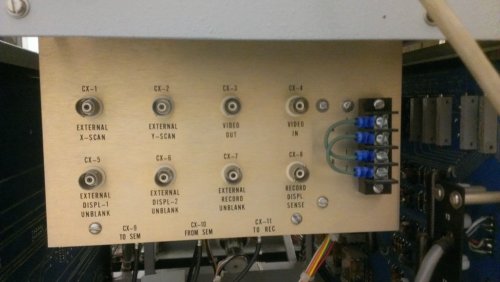

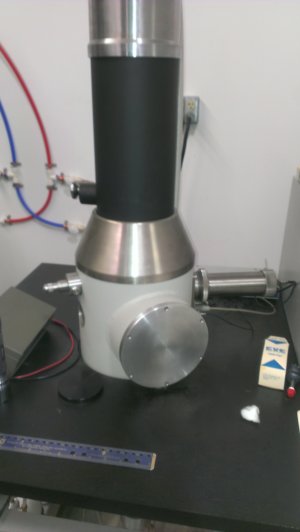

To test the many penetrations and sliding o-ring seals in the specimen chamber door I found a blanking plate of the correct size and pumped down the specimen chamber with this in place. I did not observe any changes in the pressure of the chamber with this door in place so I feel confident that these feedthroughs are sealing. The goal of this project is to restore and update an older Amray AMR-1000 scanning electron microscope to a modern work flow. This means using a digital to analog generator to bypass some of the scan generators and replacing the polaroid camera used to record images with a direct electronic read out of the image in real time.

The goal of this project is to restore and update an older Amray AMR-1000 scanning electron microscope to a modern work flow. This means using a digital to analog generator to bypass some of the scan generators and replacing the polaroid camera used to record images with a direct electronic read out of the image in real time.